Hi,

Speaking with @Lee this is not something he has come across (course had to happen to me!) I was happily screwing on the nuts for the front stabilizer bar, on the last one and it just needed one or 2 full turns to get it on tight. Upon doing one of the last turns the bolt decided to snap.

Now because this is me. It didnt snap at a nice handy length where you could get away with twisting a nut on anyway. no no. It snapped pretty much flush with the chassis with maybe 2 threads exposed.

So. My question is two fold.

1) has this ever happened to anyone

2) whats the best approach to fix this?

I was thinking of drilling out the bolt and tapping it, but i cant imagine the chassis being thick enough here to do a solid enough tap for a bolt for me to be confident in it, holding the stabilizer bar in place. - surely it would only be like 2 threads deep max

My 2nd thought was maybe to fill the area with something to harden around the bolt once tapping is done to give some extra grip, again not ideal.

My last and not ideal option is to sand the area back and weld the sucker on. but obviously would like to avoid this if possible.

Any one with some wisdom on this would be greatly appriciated.

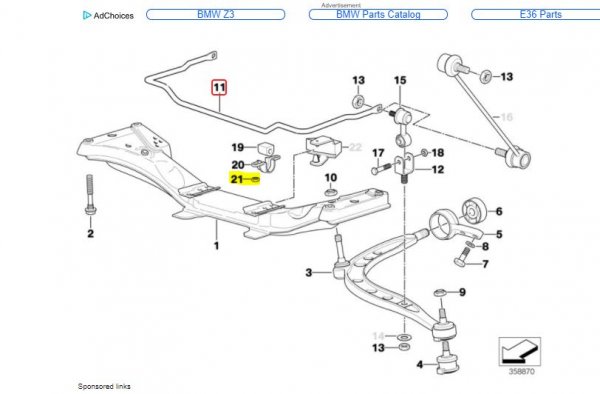

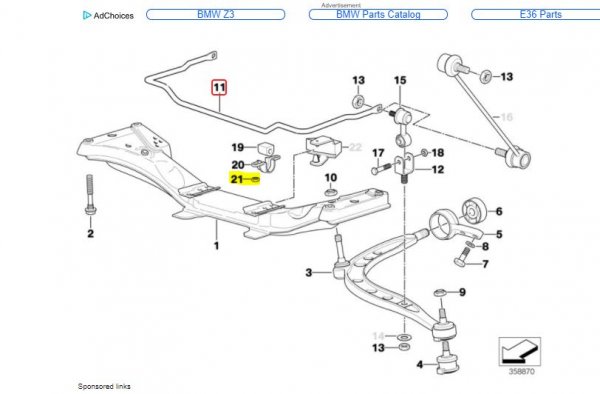

Image to show the part im referring too - bolt not in image but will give you an idea of the area im in.

Andrew

Speaking with @Lee this is not something he has come across (course had to happen to me!) I was happily screwing on the nuts for the front stabilizer bar, on the last one and it just needed one or 2 full turns to get it on tight. Upon doing one of the last turns the bolt decided to snap.

Now because this is me. It didnt snap at a nice handy length where you could get away with twisting a nut on anyway. no no. It snapped pretty much flush with the chassis with maybe 2 threads exposed.

So. My question is two fold.

1) has this ever happened to anyone

2) whats the best approach to fix this?

I was thinking of drilling out the bolt and tapping it, but i cant imagine the chassis being thick enough here to do a solid enough tap for a bolt for me to be confident in it, holding the stabilizer bar in place. - surely it would only be like 2 threads deep max

My 2nd thought was maybe to fill the area with something to harden around the bolt once tapping is done to give some extra grip, again not ideal.

My last and not ideal option is to sand the area back and weld the sucker on. but obviously would like to avoid this if possible.

Any one with some wisdom on this would be greatly appriciated.

Image to show the part im referring too - bolt not in image but will give you an idea of the area im in.

Andrew